- IC PAKCAGING THERMAL SIMULATION JOB DESCRIPTION HOW TO

- IC PAKCAGING THERMAL SIMULATION JOB DESCRIPTION SKIN

- IC PAKCAGING THERMAL SIMULATION JOB DESCRIPTION VERIFICATION

- IC PAKCAGING THERMAL SIMULATION JOB DESCRIPTION SOFTWARE

a AI or HPC processor without considering how to get the heat out is likely to lead to problems later on, resulting in a sub-optimal packaging solution from cost, size, weight and performance perspectives.

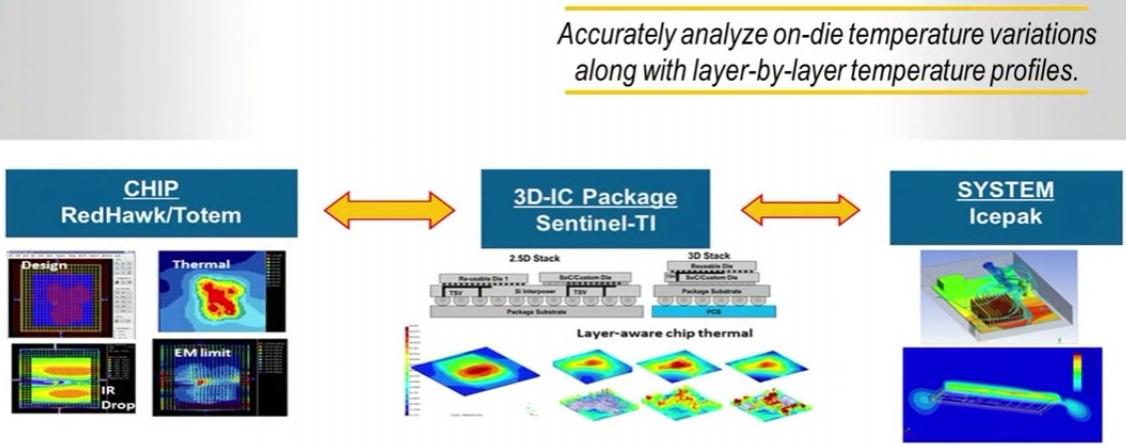

Designing a large high power device, e.g. 2.5/3D IC package thermal modeling Modeling heterogeneous 2.5/3D IC-package thermal chip-package-interactions is important for several reasons. As an integral part of Xpedition Substrate Designer, it is immediately available to all package designers.

IC PAKCAGING THERMAL SIMULATION JOB DESCRIPTION SKIN

It is ideally suited for power integrity, low-frequency SSN/SSO, and complete-system SPICE model generation while accounting for skin effect impact on resistance and inductance. Full-3D electro-magnetic-quasi-static (EMQS) extractionįull package model creation with multi-processing for faster turnaround time. Calibre xACT provides accurate parasitic extraction of TSVs, front and backside metal, and TSV to RDL coupling. For a digital design, the designer must run static timing analysis (STA) on the complete package assembly, including parasitics. Intra-die & Inter-die parasitic extractionįor an analog design, the designer must simulate the system circuitry, including parasitics. Together, these automate SERDES channel analysis while retaining accuracy. These utilize automatic channel extraction, interface-level channel compliance verification, and pre-layout design exploration. Comprehensive SERDES analysis SERDES interface analysis and optimization include FastEye diagram analysis, S-parameter simulation, and BER prediction.

IC PAKCAGING THERMAL SIMULATION JOB DESCRIPTION VERIFICATION

From pre-route design exploration and “what-if” analysis through detailed verification and sign-off, all with fast, interactive analysis, ease-of-use, and integration with Package Designer. Analyze s ignal integrity (SI) issues in the design cycle HyperLynx SI supports general-purpose SI, DDR interface signal integrity and timing analysis, power-aware analysis, and compliance analysis for popular SerDes protocols. Results can be reviewed in graphical and report formats.

Proficient in some of modelling tools such as: 3D mechanical, Ansys Maxwell. Identify potential DC power delivery issues such as excessive voltage drop, high current densities, excessive via currents and associated temperature rise including co-simulation for signal/power/thermal impact. Solid knowledge in SiC or GaN devices and related packaging technologies. Power distribution networks can be analyzed for voltage drop and switching noise issues. The semiconductor product line delivers significant advances in performance and capacity for advanced node chips, introducing new features for multi-die design's thermal and Multiphysics analysis.Analysis of voltage drop & IC switching noises Reliability issues from thermo-mechanical Stress & Warpage of multi-die assemblies.

IC PAKCAGING THERMAL SIMULATION JOB DESCRIPTION SOFTWARE

CFD software known for its advanced physics modeling and renowned for industry leading accuracy. It predicts airflow, temperature and heat transfer in IC packages, PCBs, electronic assemblies, enclosures and power electronics. Electromagnetic coupling (EMC/EMI) of interposer signals, even digital ones. A computational fluid dynamics (CFD) solver for electronics thermal management. Leading design teams have adopted these advances as they face various novel multiphysics challenges to succeed with 3D-IC. We see newtransistor architectures like nanosheet gate-all-around (GAA) and back-side power delivery.The second set of challenges facing semiconductor designers relates to multi-die design, 2.5D/3D-IC packaging, and heterogeneous integration. Semiconductor design is going through an inflection point as designers face two significant challenges rooted in manufacturing advances: The first is the ongoing march of Moore’s Law into advanced finFET process technology below 5nm. This video briefly overviews the challenges and solutions addressed by Ansys Semiconductor software products for the Electronic Design Automation (EDA) market.

0 kommentar(er)

0 kommentar(er)